PACKAGING & LOGISTICS

Pushing the Limits of Real-Time Vision Inspection for Coated Paper

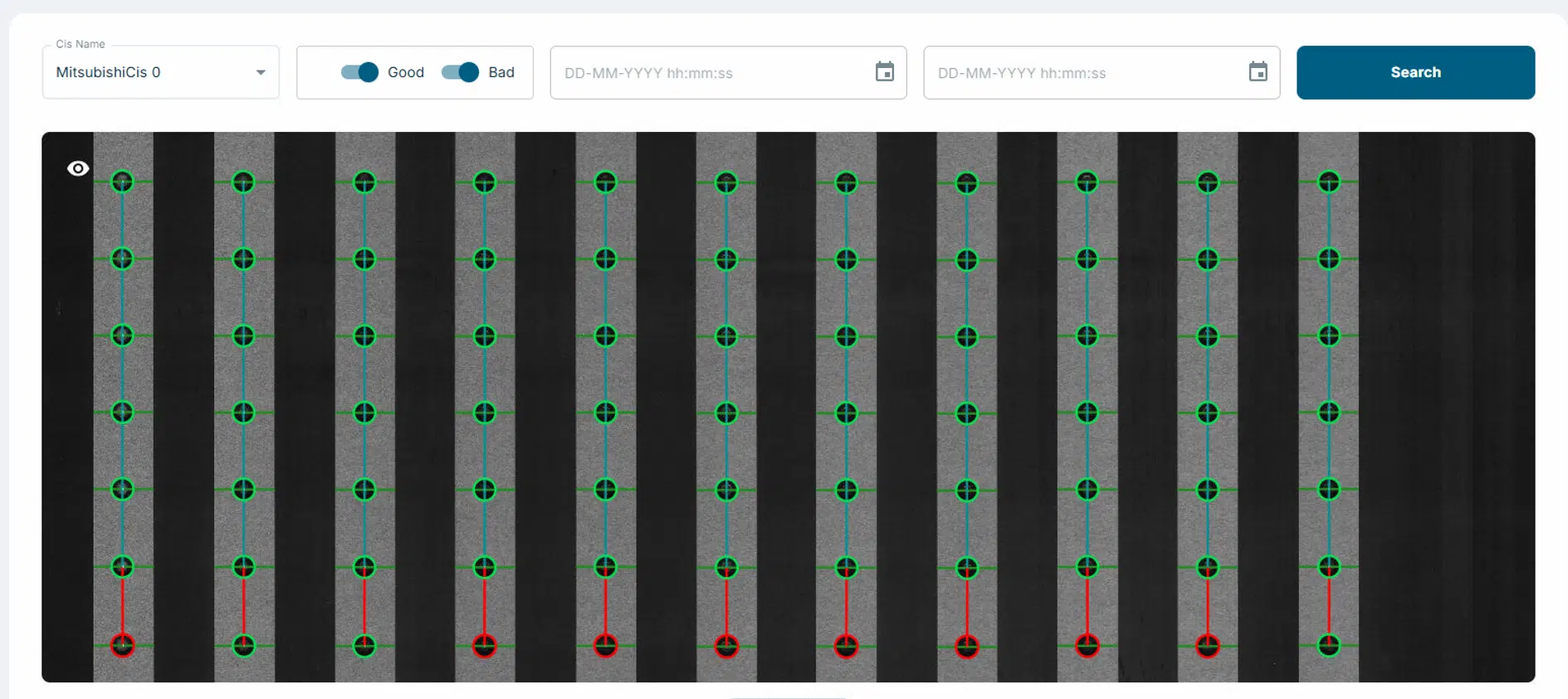

In collaboration with a leading manufacturer, we developed a high-performance real-time vision inspection coated paper system to inspect high-speed seal bands with exceptional accuracy. This standalone solution combines Mitsubishi Contact Image Sensors (CIS), custom vision algorithms, and real-time analytics to ensure product quality and production consistency.

Real-time defect detection on coated paper seal bands

To tackle the challenge of inspecting fine, repetitive features on fast-moving coated paper seal bands, our engineering team built a fully autonomous system. The solution performs precise measurements of hole diameters, spacing, centering, and strip width — across 22 bands running in parallel. The vision system performs 1 analysis on each band every 32mm at a maximum rate of 100m/min.

A key technological advantage was the use of Mitsubishi Contact Image Sensors (CIS). These sensors offer native linear resolution, built-in lighting uniformity, and a compact footprint, making them ideal for close-range, high-precision scanning of narrow materials. With this hardware choice and our grouped image processing architecture, we achieved high throughput while maintaining robustness and precision.

Scope

- Dual CIS Line Scan Cameras (11 Bands Each)

- Standalone Factory Plugin

- Dashboard with Statistics

- Report Generation Tools

- Alarm Integration

- Production Results Viewer

- Plug & Play Architecture

- Diameter & Distance Measurement

- Hole Centering & Band Width Detection

Key Performance Metrics

- 100m/min Conveyor Speed

- 1145 inspected part per second at max speed

- Paralleled and optimized processing

Project Outcome

High-Speed Precision with CIS Technology

The system delivered robust real-time inspection of paper coated seal bands in motion. Using Mitsubishi CIS cameras, we capture high-resolution, distortion-free images with consistent lighting — crucial to achieve the required accuracy. With two synchronized line scan units covering 11 bands each, and 145 elements analyzed per frame at 8 FPS, our grouped processing pipeline ensured we kept up with a 100 meters per minute pace without sacrificing quality.

Full Monitoring and Factory Integration

The software was deployed as a factory-ready plugin, featuring real-time monitoring dashboards, report generation tools, and historical data views. Integrated alarms enhanced system responsiveness, while visualization tools gave operators deeper insights into past production, improving traceability and production control.

Conclusion

Precision at High-Speed Powered by Vision

This project demonstrates how real-time vision inspection coated paper solutions powered by CIS cameras can unlock new levels of speed and precision in industrial inspection. Reliable, and designed for high-speed close-range scanning, these sensors — combined with our custom software — delivered a solution tailored to the demands of modern manufacturing.

At Akatech, we specialize in transforming complex inspection requirements into turnkey solutions. With this project, we reaffirm our ability to deliver fast, scalable, and factory-ready vision tools that meet industrial constraints without compromise.